Hot Oil Boilers

Hot Oil Boilers

* Three-pass full cylindrical design.

* Optimum cooker heat load.

* Guaranteed speed of oil circulated in serpentines (3 – 5 m / sec.).

* Orifice plate for flow control in each coil.

* Low flue gas temperature value.

* Use of St35.8 quality certified pipes according to European DIN 2448 DIN 17175.

* Use P265GH according to EN 10028 norm as boiler sheet metal.

* Insulation with aluminum sheet on rock wool of appropriate thickness.

* Specially insulated sealing lid.

WHAT IS OUR DIFFERENTS?

1- 100% x-ray (x-ray) control is applied to all joints of boiler serpentine pipes.

2- Mechanical flow control device (German origin) is used in every coil winding, which is compulsory according to DIN 4754 standard.

3- Level switch (German origin) which is required according to DIN 4754 standard and resistant to 400 ° C is used in the expansion tank.

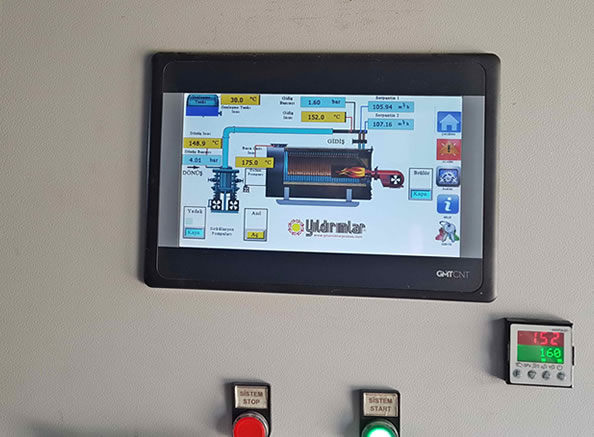

4- The amount of oil passing through each coil is digitally displayed on the PLC display and stops the burner if it is not within the limits.

5- When the oil speed reaches minimum value, the burner automatically shuts off.

6- When viscosity is low, the burner never starts at full capacity to protect the heat transfer oil.

7- The burner cannot reach full capacity until the flow rate and temperature of the oil in the coil reaches the desired value.

8- When the pressure in the system exceeds the allowed limit, the safety valve is activated and discharges the oil.

9- The burner automatically shuts off when the flow temperature exceeds the desired temperature.

10- The burner switches off automatically when the return temperature exceeds the desired temperature.

11- The burner turns off automatically when the flue gas temperature exceeds the desired temperature.

12- Heat transfer oil is circulated in the boiler at ideal speed.

13- Boiler smoke passages are watertight and sealed.

14- Flue gas temperature is low due to its special design.

15- The air – gas etc. formed in the system is easily removed thanks to the specially designed degasser.

16- The above commands and controls are easily monitored and interrupted via the touch PLC screen on the control panel.

HOT OIL BOILER ROOM

1. Hot Oil Boiler

2. Burner

3. Circulation Pump Group

4. Expansion Tank

5. Steel Platform

6. Collection Tank

7. Degasser

8. Flue

9. Electrical Panel

10. Return Pressure Transmitter

11. Manometer

12. High Temperature Control

13. Oil Flow Temperature Control

14. Flow Pressure Transmitter

15. Safety Valve

16. Oil Return Temperature Control

17. Flue Gas Temperature Control

18. Flowmeter (in every coil)

19. Manometer

20. Manovacumeter

21. Feeding Line

22. Messenger Line

23. Safety Output Line

24. Overflow Line

25. Outgoing Safety Line

26. Expansion Tank Temperature Control

27. Minimum Level Control of Expansion Tank

28. Level Indicator

29. Filling Pump

30. Commissioning Line