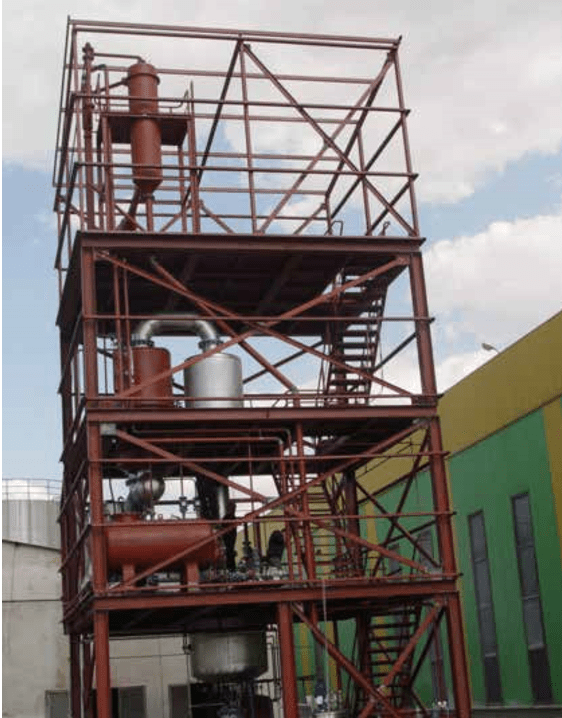

Glycerin Distillation Plants

Glycerin Distillation Plants

Prior to distillation, the technical specifications of the raw material are checked (80-82%) and then sent to the boiler via a pump. Here the temperature is raised to 80’C. The free caliper is checked and caustic is added if necessary.

The crude glycerin is then fed to the pre-dryer via the pump. The water contained in the crude glycerin passed to the pre-dryer (10% -12%) is vacuumed and sent to the barometric condenser. Crude glycerin which has been dehydrated is fed to the distillator. It is boiled under high vacuum and temperature. When the system enters the regime, glycerin starts to evaporate.

In step 1, a glycerin vapor liquid phase collision yields 9.5% purity pharmaceutical glycerine is collected in the lower tank.

In step 2, the vapor of the glycerin passing to the cooling condenser collides with the liquid phase and collects in the lower tank as 98.5% technical glycerin. Both products are dispatched to separate product storage tanks via separate pumps.

In step 3, the glycerin leaving the cooling condenser (low percentage) is collected in the intermediate tank by keeping it in the refrigerant condenser before reaching the barometric system. Glycerins collected in finished product tanks as pharmaceutical and technical products are separately packaged and stored after bleaching in tanks with an agitator.